How to cut I-beam steel effectively and accurately?

To effectively and accurately cut I-beam steel, you can use the following methods and techniques:

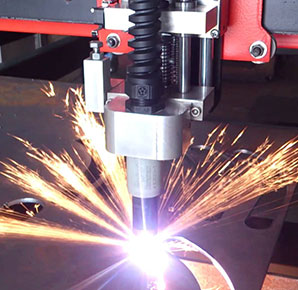

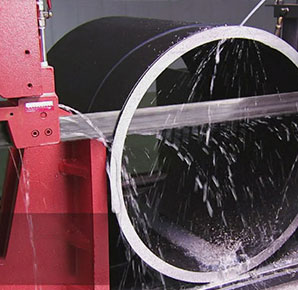

1. Use appropriate cutting tools: Choose tools suitable for cutting I-beam steel, such as flame cutters, plasma cutters, laser cutters or specialized hacksaws. Select appropriate cutting equipment based on the size and requirements of the I-beam steel.

2. Accurate measurement and marking: Use tools (e.g. tape measure, square angle) to take accurate measurements to determine cutting length and angle. Use a marker or pencil to make clear marking lines on the I-beam steel to guide the cutting operation.

3. Stably clamp the I-beam steel: Fix the I-beam on a stable workbench and clamp it with clamps or fixtures to prevent movement or vibration. Make sure the I-beam steel is securely in place to ensure precise cutting.

4. Control the cutting speed: Control the cutting speed according to the thickness of the cutting material and the capability of the cutting equipment. Cutting speeds that are too fast may result in inaccurate cut lines or poor edge quality, while cutting speeds that are too slow may produce excessive heat and thermal deformation.

5. Properly select cutting parameters: According to the material and thickness of the I-beam steel, adjust the parameters of the cutting equipment, such as oxygen/gas ratio, plasma arc flow, laser power, etc. Make sure to use the correct cutting parameters to achieve the desired cut quality and results.

6. Control the cutting angle and direction: According to the marking line or template guidance, always maintain stable hand movements and control the cutting angle and direction. Use supports or assistive devices to help maintain a straight cut.

7. Pay attention to cooling and cleaning during the cutting process: when cutting long sections continuously, cool down in time to avoid deformation caused by overheating. At the same time, regularly clean up waste and debris in the cutting area to ensure cutting quality and a clean working environment.

8. Follow safe operating procedures: During the cutting process, always follow relevant safe operating procedures, wear personal protective equipment, and make sure there are no other people or obstacles around.

By following these methods and tips, you can cut I-beam steel efficiently and accurately and get the cut quality and size you want.

CONTACT US

No limited to time and space, you can call for our online-service personnel for consultation, or fill in the table below for an enquiry. Your message will be promptly resolved.

- Tel:+86-21-61182423

- Fax:+86-21-61182425

- E-mail:[email protected]

- Skype:shanghai.katalor

- Address:Unit 6,lane 2500,xiupu Road,Kangqiao Industrial Area,Pudong New District,Shanghai

- Online Consultation

- After-sales Engineer