Detailed introduction to the surface treatment of stainless steel pipe

There are many surface treatment methods for stainless steel pipe. The following are some common details:

1. Pickling: Remove scale, welding slag and other surface impurities by soaking in strong acid, such as nitric acid or hydrochloric acid. This improves the finish and purity of the stainless steel.

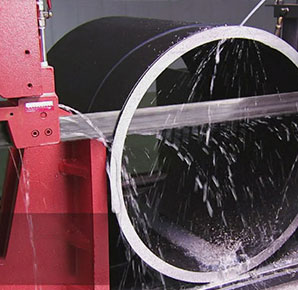

2. Mechanical polishing: Use mechanical grinding or polishing process to remove surface roughness and make it smoother. This treatment is typically used in applications that require a high finish, such as food processing equipment.

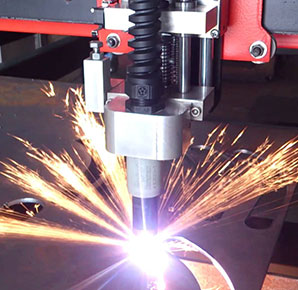

3. Sandblasting: Use high-speed airflow to impact sand or other particles onto the surface of stainless steel to remove scale, dirt and improve surface roughness. This method is often used to create surfaces with anti-slip requirements.

4. Electroplating: including chromium, nickel, zinc and other metal plating to increase the corrosion resistance and aesthetics of stainless steel pipes. Electroplating can provide an additional layer of protection and reduce the exposure of stainless steel pipes to the environment.

5. Coating: Spray or dip-coat a protective coating, such as polymer or ceramic coating, to increase the corrosion resistance and wear resistance of stainless steel pipes.

6. Heat treatment: The lattice structure of stainless steel is changed through the process of heating and cooling to adjust its hardness, strength and corrosion resistance.

7. Wire drawing: Through mechanical or chemical methods, small crisscross patterns are formed on the surface of stainless steel pipes to increase its aesthetics and scratch resistance.

8. Chemical treatment: Use chemical solutions to treat the surface of stainless steel pipe, such as pickling, passivation, etc., to change surface characteristics and increase corrosion resistance.

These surface treatment methods can be combined according to different needs and applications to achieve different functions and effects.

CONTACT US

No limited to time and space, you can call for our online-service personnel for consultation, or fill in the table below for an enquiry. Your message will be promptly resolved.

- Tel:+86-21-61182423

- Fax:+86-21-61182425

- E-mail:[email protected]

- Skype:shanghai.katalor

- Address:Unit 6,lane 2500,xiupu Road,Kangqiao Industrial Area,Pudong New District,Shanghai

- Online Consultation

- After-sales Engineer