Methods of Steel Plates Cutting

2019-11-07

Steel plates cutting refers to the use of a natural gas flame (oxygen-natural gas) to preheat the cut metal to a burning point capable of intense combustion, and then release a high pressure oxygen stream to further violently oxidize the metal and blow off the slag produced by the combustion to form a slitprocess.

Methods of Steel Plates Cutting

Flame cutting equipment is low cost and is the only cost-effective means of cutting thick metal sheets, but has its drawbacks in thin sheet cutting. Compared with plasma, the heat-affected zone of flame cutting is much larger and the thermal deformation is larger. In order to cut accurately and effectively, the operator needs to have superb technology to avoid the thermal deformation of the metal plate in the cutting process.

The laser cutting equipment can cut stainless steel below 4mm, and oxygen can cut 20mm thick carbon steel in the laser beam, but after oxygen cutting, a thin oxide film will be formed on the cutting surface. The maximum thickness of the cut can be increased to 20 mm, but the dimensional error of the cutting member is large. The price of laser cutting equipment is quite expensive, about 1.5 million yuan.

Wire cutting

Wire EDM is referred to as wire cutting. It is developed on the basis of EDM perforation and forming. It not only has the application of EDM, but also has replaced EDM and forming. Today, wire-cutting machines account for more than half of EDM machines.

Shearing machine

The shearing machine is a moving blade and a fixed lower blade. With a reasonable blade gap, shearing force is applied to the metal sheets of various thicknesses to break the plates according to the required size. Shearing machine is one of the forging machinery, the main role is the metal processing industry.

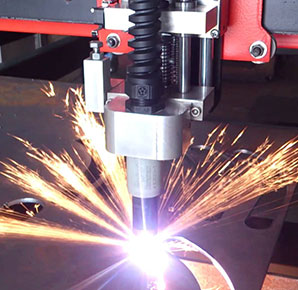

Plasma cutting machine

Plasma cutting is a processing method that uses the heat of a high temperature plasma arc to partially or partially melt (and evaporate) a metal portion at a workpiece cut and to remove the molten metal by high-speed plasma momentum to form a slit.

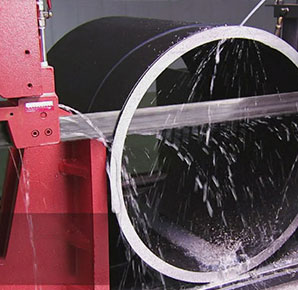

Ultra high pressure water cutting

For gases, oxygen is necessary for the combustion of combustible gases in order to provide the required energy for the ignition temperature of the steel; in addition, oxygen is necessary for the steel to be preheated to the point of ignition and then burned. The oxygen used to cut steel must have a high purity, generally required to be above 99.5%, and the industrial standards of some advanced countries require oxygen purity above 99.7%. For every 0.5% reduction in oxygen purity, the cutting speed of the steel plate is reduced by about 10%. If the oxygen purity is reduced by 0.8%-1%, not only the cutting speed is reduced by 15%-20%, but also the slit is widened. The lower end of the slit has more slag and is difficult to clean, and the quality of the cut section is also obviously deteriorated. Also with the increase. Obviously, this reduces production efficiency and cutting quality, and the production cost is significantly increased.

CONTACT US

No limited to time and space, you can call for our online-service personnel for consultation, or fill in the table below for an enquiry. Your message will be promptly resolved.

- Tel:+86-21-61182423

- Fax:+86-21-61182425

- E-mail:[email protected]

- Skype:shanghai.katalor

- Address:Unit 6,lane 2500,xiupu Road,Kangqiao Industrial Area,Pudong New District,Shanghai

- Online Consultation

- After-sales Engineer