Technical difficulties of laser cutting thick metal plate

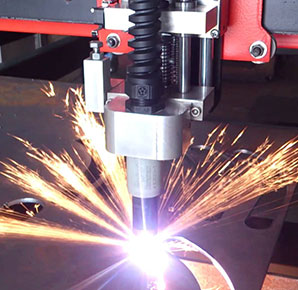

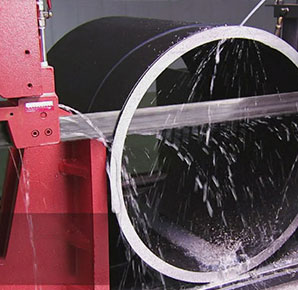

When laser cutting machine is cutting thick metal plate, the decrease of oxygen purity is one of the important factors that affect the quality of incision. The purity of oxygen flow has a great influence on the cutting process. With the decrease of oxygen purity, the combustion rate will decrease, which will greatly reduce the energy input into the cutting seam during the combustion process and reduce the cutting speed of the steel plate; at the same time, the iron content in the liquid layer of the cutting surface will increase, which will increase the viscosity of the slag and make it difficult to discharge the slag. In this way, there will be serious slag hanging at the lower part of the incision, which makes the quality of the incision difficult to accept.

In order to keep the cutting stable, the purity and pressure of oxygen flow in the direction of steel plate thickness should be kept constant. In the traditional laser cutting process, the common conical nozzle is often used, which can meet the requirements of thin plate cutting. But when cutting thick metal plate, with the increase of gas supply pressure, shock wave is easy to form in the flow field of nozzle, which has many hazards to the cutting process, reducing the purity of oxygen flow and affecting the quality of incision.

CONTACT US

No limited to time and space, you can call for our online-service personnel for consultation, or fill in the table below for an enquiry. Your message will be promptly resolved.

- Tel:+86-21-61182423

- Fax:+86-21-61182425

- E-mail:[email protected]

- Skype:shanghai.katalor

- Address:Unit 6,lane 2500,xiupu Road,Kangqiao Industrial Area,Pudong New District,Shanghai

- Online Consultation

- After-sales Engineer