What are the precautions and processes for steel plate cutting

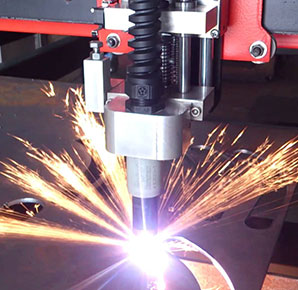

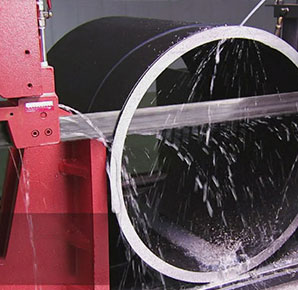

1. The cutting nozzle should be selected according to the thickness of the steel plate, and the cutting straightness and cutting speed should be adjusted to obtain good steel plate cutting quality.

2. For thick steel plate cutting, the cutting nozzle and the surface of the workpiece should be vertical. Wait until the entire section is cut before moving the cutting nozzle. When the cutting end point is about to be reached, the cutting speed should be slowed, but not too slow.

3. The cutting parameters should be adjusted according to the thickness of the steel plate, including the cutting nozzle model, gas pressure and cutting speed. Because if the parameters are not correct, it will affect the final steel plate cutting quality.

4. Before cutting the steel plate, the surface must be cleaned to remove dust, dirt and grease, so as not to affect the steel plate cutting quality.

5. When the torch moves, it should move at a uniform speed, which is more suitable.

6. If the size of the cutting piece is not the same, generally cut the small one first, and then cut the large one.

7. If straight cutting is performed, the flame intensity of each cutting nozzle should be consistent, otherwise problems will occur.

8. During the steel plate cutting process, it is necessary to observe and pay attention to the cutting situation at any time to ensure that the cutting can be continued without interruption.

9. After the steel plate cutting is completed, the cutting surface of the steel pieces should be checked for any problems or defects.

10. After the workpiece is cut, mark it after checking and confirming there are no problems.

CONTACT US

No limited to time and space, you can call for our online-service personnel for consultation, or fill in the table below for an enquiry. Your message will be promptly resolved.

- Tel:+86-21-61182423

- Fax:+86-21-61182425

- E-mail:[email protected]

- Skype:shanghai.katalor

- Address:Unit 6,lane 2500,xiupu Road,Kangqiao Industrial Area,Pudong New District,Shanghai

- Online Consultation

- After-sales Engineer