What’s Flame Cutting?

Description

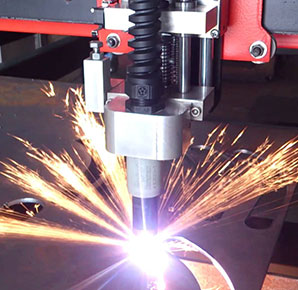

Flame cutting, also called oxy-fuel cutting, consists of a number of cutting processes used to cut metals by means of the chemical reaction of oxygen with the base metal at elevated temperatures. It is oxygen cutting in which the appropriate part of the material to be cut is raised to ignition temperature by an oxy-fuel gas flame.

Flame cutting process is used for separating and shaping steel components. It is carried out using a torch through which oxygen and a fuel gas (acetylene, propane or mains gas) are passed. An outer ring of jets in the torch nozzle are used to preheat the surface of the steel. A separate oxygen stream is directed from a central jet on to the area to be cut. Rapid oxidation of the steel takes place and material is removed by the pressure of the gases.

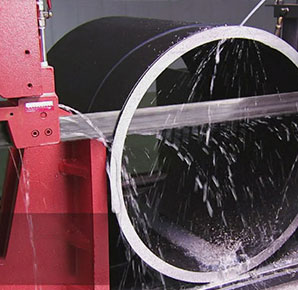

The process may be manual, where the cutting torch is held and guided by the operator, or mechanised, where the torch may be mounted on a machine. Cutting of complex shapes is possible. Cutting machines may be pre-programmed, using computer technology, to minimise material wastage of plate being cut. Multi-cutting head machines are available for high volume production applications.

CONTACT US

No limited to time and space, you can call for our online-service personnel for consultation, or fill in the table below for an enquiry. Your message will be promptly resolved.

- Tel:+86-21-61182423

- Fax:+86-21-61182425

- E-mail:[email protected]

- Skype:shanghai.katalor

- Address:Unit 6,lane 2500,xiupu Road,Kangqiao Industrial Area,Pudong New District,Shanghai

- Online Consultation

- After-sales Engineer