What should we pay attention to when cutting SS400 steel plate?

When cutting SS400 steel plate, you need to pay attention to the following points:

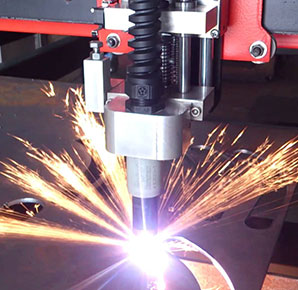

1. Use appropriate cutting tools: Choose appropriate cutting tools, such as laser cutters, plasma cutters or oxy-fuel cutters to ensure cutting results and safety.

2. Safety protection measures: Wear personal protective equipment, such as goggles, gloves and earplugs, to avoid physical harm from sparks, splashes and noise generated during the cutting process.

3. Prepare a stable workbench: Place the SS400 steel plate on a stable workbench to ensure its stability and avoid movement or shaking during the cutting process.

4. Select appropriate cutting parameters: According to the cutting tool used and the thickness of the SS400 steel plate, adjust parameters such as cutting speed, cutting depth, and cutting angle to obtain ideal cutting results.

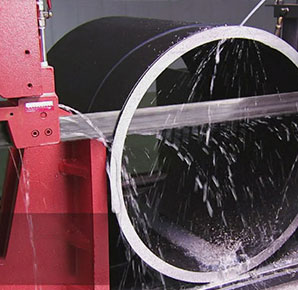

5. Avoid overheating: During the cutting process, avoid overheating the SS400 steel plate to avoid affecting the performance of the material. Appropriate cooling measures, such as water spray or air cooling, can be taken to reduce the temperature of the cutting area.

6. Plan the cutting path: Plan the cutting path reasonably to avoid repeated cutting and excessive wear of the tool. Ensure the cutting path is clear and accurately control the cutting direction.

7. Check the cutting tools regularly: Check the wear of the cutting tools regularly, and replace the blade or cutting nozzle in time to ensure the cutting effect and safety.

Please note that the above provides general advice only. Before cutting steel plates, please refer to the instructions for use of cutting tools and equipment and follow appropriate safety operating procedures.

CONTACT US

No limited to time and space, you can call for our online-service personnel for consultation, or fill in the table below for an enquiry. Your message will be promptly resolved.

- Tel:+86-21-61182423

- Fax:+86-21-61182425

- E-mail:[email protected]

- Skype:shanghai.katalor

- Address:Unit 6,lane 2500,xiupu Road,Kangqiao Industrial Area,Pudong New District,Shanghai

- Online Consultation

- After-sales Engineer