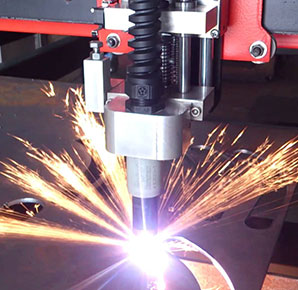

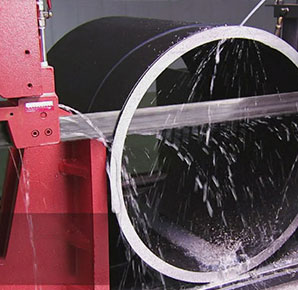

The reason of steel plate cutting hanging slag

There can be many reasons for hanging slag in steel plate cutting, and the following are some possible factors:

1. Improper cutting parameters: When cutting, if the cutting speed is too fast, the feed speed is too high, or the cutting gas flow is insufficient, the cutting parameters are improperly set, which may lead to slag hanging problems.

2. Tool wear: Cutting with severely worn tools will increase the risk of hanging slag. Blunt drilling or cutting blades can cause inadequate melting and shearing, resulting in hanging slag.

3. Material quality: Some low-quality steel may contain excessive impurities, inclusions or uneven organization, which will affect the quality of cutting and produce hanging slag phenomenon.

4. Cutting gas quality: The quality of cutting gas also has an impact on the problem of hanging slag. Impure cutting gases (e.g. moisture in the air, impurities, etc.) can lead to hanging slag.

5. Cutting surface state: If there are impurities such as grease, rust, coating on the surface of the steel plate before cutting, it will have an adverse effect on the cutting process, which may lead to hanging slag.

Solutions to the problem of hanging slag include:

- Optimize cutting parameters: Adjust cutting speed, feed speed, cutting gas flow and other parameters to make it suitable for specific materials and tools.

- Use good tools: Make sure the tools are sharp and replace badly worn blades in time.

Select high quality materials: Use steel that has been tested for quality and meets the requirements.

- Ensure that the cutting area is clean: clean the surface of grease, coating and other impurities before cutting.

- Use pure cutting gas: Use pure, dry cutting gas to avoid moisture and impurities in the gas to affect the cutting process.

If the problem still exists, it is recommended to consult us, we are professional cutting equipment suppliers and process experts, in order to give more specific technical guidance and solutions.

CONTACT US

No limited to time and space, you can call for our online-service personnel for consultation, or fill in the table below for an enquiry. Your message will be promptly resolved.

- Tel:+86-21-61182423

- Fax:+86-21-61182425

- E-mail:[email protected]

- Skype:shanghai.katalor

- Address:Unit 6,lane 2500,xiupu Road,Kangqiao Industrial Area,Pudong New District,Shanghai

- Online Consultation

- After-sales Engineer