What are the precautions of seamless steel pipe cutting process?

Seamless steel pipe cutting is an operation with a certain risk, need to pay attention to the following matters:

1. Safety protection: Before performing the cutting operation, ensure that you wear appropriate personal protective equipment, such as safety glasses, gloves and earplugs. Ensure that the operating environment is well ventilated and that relevant safety procedures are followed.

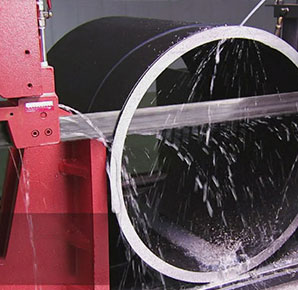

2. Cutting tool selection: Select tools suitable for seamless steel pipe cutting, such as suitable cutting machinery, cutting disc or cutting flame spray gun. Ensure that the cutting tools are of reliable quality and meet the standard requirements.

3. Material preparation: Before the cutting starts, the seamless steel pipe is fixed to ensure its stability. Remove debris and combustibles around the cutting area to prevent fire and accidental injury.

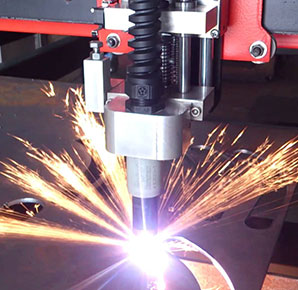

4. Cutting operation skills: Follow the correct cutting technology and operating steps. According to the needs, choose the appropriate cutting method, such as mechanical cutting, gas cutting or laser cutting. Master the correct cutting speed and force to avoid material damage or excessive heat generation.

5. Fire fighting measures: Prepare fire fighting equipment or other appropriate fire fighting equipment, and ensure that there is supervision during operation. Remove sparks in time during cutting to reduce fire risk.

6. Post-cutting treatment: After cutting, clean up the debris and residue in the cutting area in time. Dispose of waste properly to ensure a clean environment.

7. Training and experience: Seamless steel pipe cutting is a job that requires experience and skills. If you do not have enough experience, it is recommended to receive relevant training or seek the help of a professional to ensure a safe and effective cutting operation.

Specific precautions may vary depending on cutting equipment, materials, and other factors. Before cutting seamless steel pipes, refer to the relevant safety guide and operation manual to ensure that the operation is carried out in the correct way.

CONTACT US

No limited to time and space, you can call for our online-service personnel for consultation, or fill in the table below for an enquiry. Your message will be promptly resolved.

- Tel:+86-21-61182423

- Fax:+86-21-61182425

- E-mail:[email protected]

- Skype:shanghai.katalor

- Address:Unit 6,lane 2500,xiupu Road,Kangqiao Industrial Area,Pudong New District,Shanghai

- Online Consultation

- After-sales Engineer