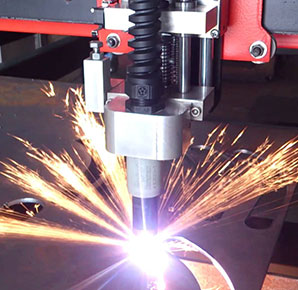

Laser cutting process of thick steel plate

The process of laser cutting thick steel plate usually includes the following steps:

1. Material preparation: Fix the steel plate on the cutting machine and ensure its flatness and stability to ensure the cutting quality.

2. Laser parameter setting: According to the material and thickness of the steel plate, adjust the power of the laser, the focal length of the focusing lens and the cutting speed and other parameters to obtain the best cutting effect.

3. Focusing the laser beam: Use convex or concave lenses to focus the laser beam and focus it on a smaller point to improve the energy density.

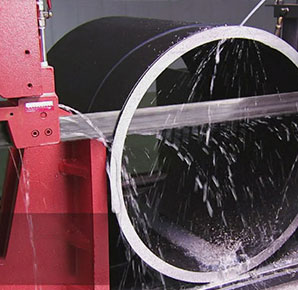

4. Cutting operation: Start the laser and irradiate the high-energy laser beam to the predetermined position on the surface of the steel plate. The energy of the laser causes local areas of the steel plate to heat up quickly and melt.

5. Gas injection: Auxiliary gas (such as oxygen and nitrogen) is provided to the cutting area through the jet nozzle to accelerate the discharge of melted metal from the cutting joint, and cool the cutting area to prevent the cutting joint from re-solidifying.

6. Control movement: Control the laser cutting machine bed along the predetermined path, so that the laser beam on the steel plate for continuous cutting. Computer numerical control (CNC) systems are often used to achieve accurate motion control.

7. Cutting completion and post-treatment: When the cutting of the required shape is completed, stop the laser and carry out the necessary post-treatment work, such as removing the residual gas, cleaning the cutting area and surface treatment.

It should be noted that the laser cutting process of thick steel plates may involve high energy and process parameters, and the requirements for equipment are also high to ensure cutting quality and safety.

CONTACT US

No limited to time and space, you can call for our online-service personnel for consultation, or fill in the table below for an enquiry. Your message will be promptly resolved.

- Tel:+86-21-61182423

- Fax:+86-21-61182425

- E-mail:[email protected]

- Skype:shanghai.katalor

- Address:Unit 6,lane 2500,xiupu Road,Kangqiao Industrial Area,Pudong New District,Shanghai

- Online Consultation

- After-sales Engineer