How to avoid heat-affected zones and edge deformation when cutting I-beam steel

To avoid heat-affected zones and edge deformation as much as possible, the following points can be considered when cutting I-beam steel:

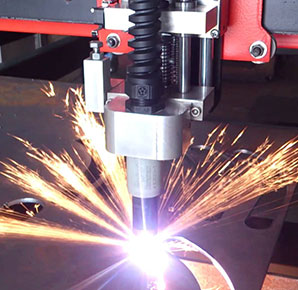

1. Choose the right cutting method: Choosing the right cutting method can help reduce heat-affected zones and edge deformation. For example, plasma cutting generally has a smaller heat affected zone than flame cutting.

2. Control cutting parameters: Adjust cutting parameters, such as cutting speed, gas flow, current density, etc., to minimize heat input and reduce the size of the heat-affected zone.

3. Use the right tool: Choosing the right tool, such as an alloy tool, can improve the quality of your cut and reduce the risk of deformation.

4. Preheating and post-processing: For thicker I-beam steel, proper preheating before cutting can reduce stress accumulation and deformation. After cutting is completed, timely processing of the edges, such as grinding to remove burrs, can also help reduce deformation.

5. Fix the workpiece: Make sure the I-beam is firmly fixed on the cutting table to prevent uneven heating and deformation caused by movement or vibration during cutting.

6. Control the cutting angle: Try to cut the workpiece vertically to avoid bevel cutting, which is more likely to cause deformation.

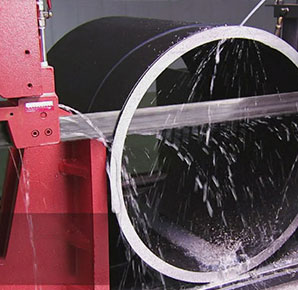

7. Cooling: Use appropriate cooling methods, such as water spray cooling, to cool the workpiece surface in time during the cutting process, which will help reduce the heat-affected zone.

8. Optimize the process: Adjust the cutting process according to the specific situation, test different parameter combinations, and find the best cutting solution to reduce the heat-affected zone and edge deformation.

By comprehensively considering the above factors and taking corresponding measures according to the actual situation, the heat-affected zone and edge deformation problems that occur during cutting of I-beam steel can be effectively reduced.

CONTACT US

No limited to time and space, you can call for our online-service personnel for consultation, or fill in the table below for an enquiry. Your message will be promptly resolved.

- Tel:+86-21-61182423

- Fax:+86-21-61182425

- E-mail:[email protected]

- Skype:shanghai.katalor

- Address:Unit 6,lane 2500,xiupu Road,Kangqiao Industrial Area,Pudong New District,Shanghai

- Online Consultation

- After-sales Engineer