Stainless steel pipe cutting method

There are many ways to cut stainless steel pipe. Common cutting methods include:

1. Mechanical cutting: cutting using mechanical equipment (such as sawing machines, circular saws, etc.). This method is suitable for thicker pipes and simple cutting needs.

2. Manual cutting: cutting with hand tools (such as hand saw, wire saw, etc.). This method is suitable for some simple cutting tasks, but is less efficient.

3. Gas cutting: Use the high-temperature flame generated by the mixed combustion of oxygen and gas to cut stainless steel pipes. Gas cutting is faster but may leave oxide in the cut.

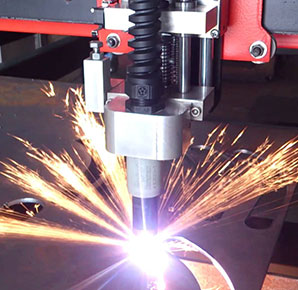

4. Plasma cutting: Use plasma arc to cut stainless steel pipe at high speed. Plasma cutting is fast and has good cut quality, but the equipment cost is high.

5. Laser cutting: The laser beam is used to cut stainless steel pipe, which is suitable for complex shapes and high precision requirements. Laser cutting is fast and the cuts are smooth, but equipment investment and maintenance costs are high.

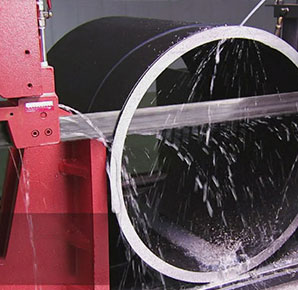

6. Water cutting: Use high-pressure water jets to cut stainless steel pipe. It is suitable for situations that are sensitive to the impact of materials, such as stainless steel pipe. Water cutting cuts smoothly and has no heat-affected zone, but it requires a lot of water resources.

When selecting a cutting method, a comprehensive evaluation must be conducted based on factors such as specific workpiece requirements, material properties, cost considerations, and process requirements to select the most suitable cutting method.

CONTACT US

No limited to time and space, you can call for our online-service personnel for consultation, or fill in the table below for an enquiry. Your message will be promptly resolved.

- Tel:+86-21-61182423

- Fax:+86-21-61182425

- E-mail:[email protected]

- Skype:shanghai.katalor

- Address:Unit 6,lane 2500,xiupu Road,Kangqiao Industrial Area,Pudong New District,Shanghai

- Online Consultation

- After-sales Engineer