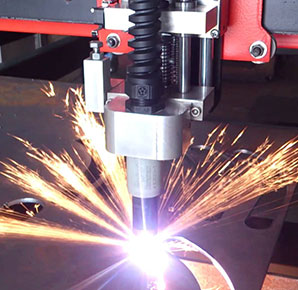

How to Use CNC Flame Cutting Machine Cut Heavy Plates?

2019-10-16

The CNC flame cutting machine generally uses a neutral flame or a slight oxidation flame when cutting. In the cutting process, the strength of the flame should be moderate, and the preheating flame should be selected according to the thickness of the workpiece, the type of cutting nozzle and the quality requirements.

In the gas cutting thick steel plate, the gantry type CNC flame cutting machine has a slow gas cutting speed. In order to prevent the upper edge of the slit from melting, the flame energy rate should be reduced accordingly; if the flame energy rate is too large, the upper edge of the slit will produce continuous beads. The steel granules are even melted into rounded corners, which also causes the adhesion of slag on the back of the kerf to increase, which affects the quality of the gas cutting. For example, when cutting a thin steel plate, the gas cutting speed is fast, and the flame energy rate can be increased accordingly, but the cutting nozzle should be farther away from the workpiece and maintain a certain inclination angle; if the flame energy rate is too small, the workpiece cannot get enough heat. Will slow down the gas cutting speed and even interrupt the gas cutting process.

Here are some tips from katalor steel summary:

1. The power of the preheating flame should increase as the thickness of the plate increases. The thicker the cutting piece, the greater the preheating flame power;

2. When cutting thick steel plates/heavy plates, a mild carbonized flame should be used to prevent the upper edge of the incision from collapsing and also to make the outer flame longer.

3. When using a diffusion type cutting nozzle and an oxygen curtain cutting nozzle to cut a steel plate with a thickness of 200 mm or less, the flame power is selected to be larger to accelerate the leading edge of the slit to the ignition point, thereby obtaining a higher cutting speed.

4. When cutting steel with high carbon content or alloying elements, because of their higher ignition point, the preheating flame power is larger.

5. When cutting the groove with a single cutting nozzle, the slag is blown to the outside of the slit to increase the energy of the flame.

CONTACT US

No limited to time and space, you can call for our online-service personnel for consultation, or fill in the table below for an enquiry. Your message will be promptly resolved.

- Tel:+86-21-61182423

- Fax:+86-21-61182425

- E-mail:[email protected]

- Skype:shanghai.katalor

- Address:Unit 6,lane 2500,xiupu Road,Kangqiao Industrial Area,Pudong New District,Shanghai

- Online Consultation

- After-sales Engineer