Principle of Surface Pretreatment of Steel Plate

2019-10-10

First, the principle of steel plate surface pretreatment

The surface pretreatment of steel sheet in the processing of steel sheet blanking refers to the treatment process of surface rust removal and a primer coating on the steel sheet under the condition of raw materials. The surface pretreatment of the steel plate includes two parts: steel plate blasting pretreatment and painting treatment.

The steel plate shot blasting pretreatment is to accelerate the abrasive (steel shot, steel wire section, angular steel grit, etc.) by the centrifugal force generated when the high speed blasting machine rotates at a high speed, and the abrasive is shot at a high speed on the surface of the treated steel to produce a blow and The grinding action removes the corrosion of the scale of the steel oxide on the surface of the steel, so that the surface of the steel is exposed to the metallic color and exhibits a certain roughness so that the coating adheres.

Spraying treatment refers to a spraying process in which the steel plate after shot blasting is automatically sprayed by a high-pressure automatic spray gun to obtain a uniform paint film on the surface of the steel sheet.

Second, the surface pretreatment characteristics of the steel plate

Shot blasting

Shot blasting not only can quickly and accurately remove rust and scale, but after shot blasting, the steel plate is evenly cleaned and has uniform roughness, which can improve the adhesion of the coating during coating and prolong the service life of the coating.

Improve the fatigue strength and corrosion resistance of materials

When shot blasting, the surface of the steel plate is strengthened by the impact of the weak shot, which improves the fatigue strength and corrosion resistance of the material and eliminates the internal stress of the weld. At the same time, the hull and other parts are subjected to strong projectile ejection during the overall rust removal of the shot blasting. It will expose the hidden cracks on the board or the excessive corrosion of the shell, which can play a role in comprehensively checking the quality of the shell.

Steel plate processing tools and equipment

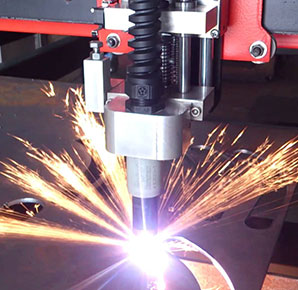

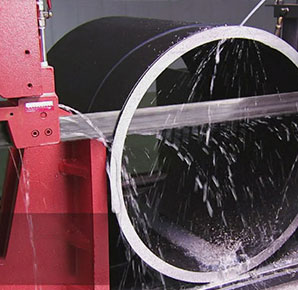

The types of steel plate cutting tools generally include flame cutting, laser cutting, wire cutting, shearing machines, plasma cutting machines, and ultra-high pressure water cutting. The most basic equipment generally includes:

1. Drilling machine: used to machine the hole on the iron plate.

Second, the planer: used to process the iron plate plane.

Third, oxygen cutting: used to cut iron plates.

Fourth, electric welding: used to weld iron plates and other workpieces.

In the special thick platecutting process, the commonly used tools include cutting tools, welding tools, drilling tools and polishing tools. Electric cutting machines, electric welders, electric drills, bench drills, and grinders are used. , sanders and small lathes.

CONTACT US

No limited to time and space, you can call for our online-service personnel for consultation, or fill in the table below for an enquiry. Your message will be promptly resolved.

- Tel:+86-21-61182423

- Fax:+86-21-61182425

- E-mail:[email protected]

- Skype:shanghai.katalor

- Address:Unit 6,lane 2500,xiupu Road,Kangqiao Industrial Area,Pudong New District,Shanghai

- Online Consultation

- After-sales Engineer